| |

This was the first tech article I ever wrote for the z32, back in 2002, way before I ever had any notions about having a web site dedicated to these cars. I think the article is a little rough, but folks tell me they still find the info useful, so here it is, if nothing else for its "historical" perspective, lol. I cringe when I read it. There is an excellent "How To" article on this subject on TT.net.

Having gone through my first plenum pull, I can hopefully make some quasi-intelligent suggestions on what to replace while the plenum is off. This is not a "how to" but sort of a "what to." To veterans, this stuff may be old hat and obvious, but I could’ve used a write-up like this before I started the job. My 1992 300ZX Twin Turbo had 91,000 miles on it at the time. SpdDemon (Harry) did the lion's share of the work. He was basically three times faster than me, with better quality work. Major helping and strong hands were also lent from Spencer and YugoBernie (Bernie). Garage was generously provided by Bruce_Zee (Jon), who remained unaffected when the job spilled over to the wee hours of the morning. Either find someone who knows what they are doing or plan on being in absolutely no hurry to get it done. I took advantage of the kind nature of my TwinTurbo.net friends and contacts.

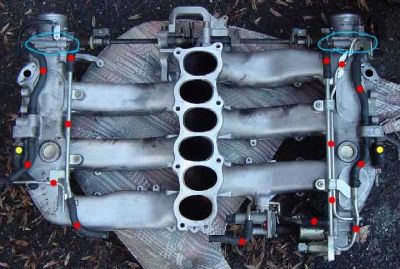

Here’s a photo of the engine with the plenum off. I marked the coil pack connectors with yellow dots, and the fuel injector connectors with the red dots, for no particular reason other than you can now see the whole main harness in the engine bay, kinda.

Larger pic here. Larger pic here.

Basically, the whole job started because of a fuel leak. That "Bastard Piece of Hose from Hell," which connects the front of the fuel rails. The two clamps on this hose are shown by the green arrows. The short, black hose between the clamps can be clearly seen just above the center of the timing belt cover, between the green arrows. Three inches of fuel injection line nearly inaccessible to replacement without removing the whole upper plenum. Dontcha' just love Z engineering at times?

We came close at least three times to making a run to the hardware or auto parts store, and that was with four guys who each essentially had a complete set of tools. We did work-arounds for each problem but I consider that lucky. The most useful tools we used that I didn't already own (I do now) were eleven-inch long, curved, needle nose pliers, and long, hose pliers, shown resting on top - notice the tips. They were indispensable for removing clamps and hoses in hard to get at places. We came close at least three times to making a run to the hardware or auto parts store, and that was with four guys who each essentially had a complete set of tools. We did work-arounds for each problem but I consider that lucky. The most useful tools we used that I didn't already own (I do now) were eleven-inch long, curved, needle nose pliers, and long, hose pliers, shown resting on top - notice the tips. They were indispensable for removing clamps and hoses in hard to get at places.

You will need some gaskets. The most important one is the large plenum gasket. For about seven bucks more, you can get a couple of EGR plenum gaskets and an AAC/IAC valve gasket.

I already had a set of new Nismo 555cc injectors sitting on the shelf. The car was still on its original set, and ran perfectly. After thinking about it for around two seconds, the choice was clear. Replace the injectors. That significantly complicated the job, but not as complicated as putting the plenum back on and finding out a month later that my injectors were failing. If you don't have the dough-re-mi for the injectors, then you can always Dremel them out one at a time in the future with the plenum on, but often when one starts to go the others follow. I was satisfied with the 91K I had gotten out of my injectors and decided to replace them while the plenum was pulled.

Here is a Rube Goldberg device we rigged for removing the fuel injectors from the rail. Removing the old injectors without damaging them can be tricky business. The garage was very cold which didn't help matters.

That is a large C-clamp, a couple of sockets on the top of the rail, a long skinny socket over the pintle, the handle of a 3/4 socket wrench, and two sets of hands, lolam. The funny thing was, it worked great. Pushed the injectors out smooth as butter. That is a large C-clamp, a couple of sockets on the top of the rail, a long skinny socket over the pintle, the handle of a 3/4 socket wrench, and two sets of hands, lolam. The funny thing was, it worked great. Pushed the injectors out smooth as butter.

If you upgrade your injectors, you must upgrade you ECU as well. If your ECU is already socketed from a previous upgrade, then you just need the EPROM chip. Each time you upgrade your chip, you pay money unless your name is Jim Wolf or Ash. Figure out whether or not you want to upgrade to the dual POP intake at the same time so that you can get the EPROM reprogrammed all at once. I didn't need a dual POP intake at my level of mods.

Most folks know you need to buy two, different sized rubber O-rings for each injector, upper and lower. There is a third rubber sleeve that is seated in the injector socket, not the rail. I would replace these too since each one of them showed signs of wear on my car.

Replace the Phillips screws that attach the fuel injectors to the rail with stainless steel hollow set screws. The old ones are a bitch to get off and you will usually strip one or two. We needed Vise Grips on a few of them. Nissan sells a replacement set of upgraded screws, as does wcoffey from TwinTurbo.net. His customer service was excellent.

Once the plenum is off I highly recommend doing the throttle body (TB) water bypass. I was amazed at all the hardware and hoses underneath the plenum that were eliminated as part of this mod, shown below marked with red dots and in a larger photo here.

These hoses should all be replaced if you don’t do the bypass. These hoses should all be replaced if you don’t do the bypass.

I studied this system the best I could to try and understand the purpose behind this tangle of metal hardlines and rubber hoses IMHO, most peeps don't understand the function of the TB water lines. They have nothing to do with air intake temps at the plenum.

The main function is to heat the throttle body butterfly pivot points by direct heat CONDUCTION through the metal sleeves circled in blue above. These metal sleeves are built into the TB's and represent the furthest point of travel for the circulating water in the TB system. The entire system exists to get the heated water to these spots underneath the plenum.

Radiant heat is not a factor. Heat by conduction from the areas circled in blue prevents icing of the butterfly pivot points when cruising at highway speeds at steady throttle.

There aren't any performance issues with doing the TB bypass. Even the icing risk is more of a legal-liability issue than a true safety risk. Imagine the Nissan engineers knowing that there was a risk of icing, however remote, and they did nothing about it. I know of ONE real-world case where the TB bypass may have lead to the throttle briefly sticking. This occurred at below freezing temps, at highway speeds, on level terrain, with the cruise control set. The sticking throttle was instantly relieved by a judicious tap on the gas pedal. If there are other cases out there, please let me know through the Contact page on this Web site.

Here is my plenum after all the extra hardware underneath was removed. Much cleaner. The hardware can left in place after the bypass since it is hidden under the plenum. Much cleaner. Here is my plenum after all the extra hardware underneath was removed. Much cleaner. The hardware can left in place after the bypass since it is hidden under the plenum. Much cleaner.

In the "You're-Crazy-if-You-Don't-Replace-Them" department would be the PCV valves. Buy the OEM, five-hose kit. There is a later version where three of the five hoses contain metal restrictors inside to quiet down any noise from the PCV valves. The old and replacement part numbers are shown below, as based on Nissan Technical Service Bulletin (TSB) NTB91-040 PCV valve noise. I believe you will automatically get the new parts as long as you order OEM, but it's worth checking out to make sure. Reportedly, if you use the PCV hoses without the restrictors, the PCV's get loud enough to be mistaken for tappet noise.

| part name | new part | old part | | valve assembly control | 11810-40P00 | 11810-30P00 | | hose blow by | 11823-30P01 | 11826-30P01 | | hose blow by | 11823-30P11 | 11826-30P11 |

Replace both PCV's valves, one on each side underneath the plenum, shown under the yellow dots. Theoretically it is possible to change the valves with the plenum in, but it is infinitely easier with the plenum off. As with most things Z, there is an easy side, and a hard side. You’ll know which is which by the time you are done.

Once you've dug that deep into your engine, you've pulled or disconnected most of your fuel and vacuum lines. Replace them. Use high quality fuel injector line and silicone vacuum lines. Nissan OEM is great, but expensive. For the vacuum lines I recommend either Hose Techniques or Baker Precision. You can buy car specific kits, or make it simpler and buy 20 feet each of four millimeter and six millimeter hose. HTS is another source that looks interesting but I do not have any personal experience with them. If you order from HTS, let me know how you like the product and service. When replacing vacuum lines, do one at a time so you don’t get your connections confused.

For the fuel injection line, I started with seven feet of the expensive, eight-millimeter Nissan hose, which sells for $1.14 per INCH, or about one hundred bucks for the seven feet. As long as you are sure to buy high-pressure, fuel inection line, then you can use 5/16", which is only 1/400" smaller than 8mm, or in other words, essentially identical in diameter for all practical purposes. The neighborhood auto parts store will carry 5/16" fuel injection line for A LOT cheaper than the Nissan brand. Just be sure NOT to use plain fuel hoses designed for carbureted engines. Ordinary fuel line will not hold up to the high pressure of fuel injection, and therefore fail and possibly make car go boom, thus ending the love affair with your Z.

By the time we were done, there were only a few inches of the fuel injection line left, but I had used the fuel injection line to also do the throttle body bypass. This was overkill and an expensive way to do the TB bypass, but I already had the line on hand so we used it. Instead, for the TB bypass, you can use much less expensive generic heater hose or regular fuel line since the regular TB hoses just carry hot water and are not under the same high pressure as the fuel injection system.

Two last parts you can replace if you want are the fuel damper and fuel pressure regulator on top of the plenum. These parts are NOT dependent on plenum removal if you want to wait, but are still under the category of good preventive maintenance.

When you get everything put back together don't immediately panic if your car runs like sh*t at first for a few minutes. Mine did. I don't know if it was the fuel pressure building back up, or the ECU relearning the set up, but after several minutes, the car ran fine. Then I was in safety boost until I found the boost solenoid on the passenger side was not connected. Snapped that back together and the car ran perfect. And no fuel leaks.

Hope this helps!

| |