| |

I replaced all the exterior body moldings on my 1992 300ZX Twin Turbo with new, OEM pieces, as if there were any other kind, lol. These included the long pieces on the sides of the windshield, the two, short, little roof pieces behind the T-tops that are just a few inches long, the long door pieces that sit on the edge where the glass goes in and out of the door, and the T-top pieces.

The molding around the rear, side quarter panel glass is part of the glass, and this molding cannot be replaced separately without changing out the entire glass piece. I left mine in place. The overall job is not hard if you take your time. All the molding sections attach to the Z in different ways.

Here are the part numbers:

windshield molding RH 72760-30P00

windshield molding LH 72761-30P00

roof molding RH (short piece) 73852-30P00

roof molding LH (short piece) 73853-30P00

door molding RH 80820-30P01

door molding LH 80821-30P01

T-top molding RH 91784-30P20

T-top molding LH 91875-30P20

clip molding 73856-30P10

These are needed for the roof pieces. Get 4-6 clips. They're only a buck each.

The price for everything is around $350. I bought mine from Coz at Concept Z.

Courtesy Nissan also sells all the molding pieces as a "kit."

You can spell it molding or moulding, and in fact Nissan spells it both ways.

WINDSHIELD MOLDING

For the long moldings on the sides of the windshield, there are several, evenly spaced clips that are part of the underside of the molding that attach to the car. The clips come already attached to the new molding, except for the top-most clip nearest the T-top, which is attached to the body of the car.

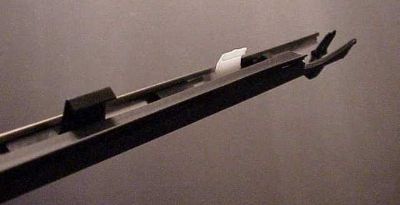

The first photo shows the underside of the end of the new windshield molding that went under the hood of the car. There is one black clip as shown, then four white clips that are evenly spaced along the molding.

You can buy a plastic tool called a "fastener remover" that looks like a giant two-pronged fork with broad, rounded tines, or you can do what I did and use your fingers and a screwdriver with a rag for padding to carefully pry these pieces off. Don't crack your windshield.

Open the hood. First see if you can slide the molding along its channel a few inches toward the T-tops. Both of mine slid easily. This caused the molding to pop free from the top most clip. These top clips stayed attached to my car on both sides. The passenger side clip is shown in the photo below, with the old molding already removed.

These clips are the same style of white clip used for the short roof pieces, behind the T-tops. I reused the old clips for the windshield molding since these clips never came off the body of the car.

Once you have the molding free from this top clip, the rest of the molding length is simply pried free. The remaining clips are attached on the outboard side of the molding strip, closer to the body pillar than the windshield glass. There are four of them, buried into a plastic channel groove the service manual called the "molding fastener."

The trick to removing the molding without bending or crimping it, is to only pry at the points where the fasteners are attached. You do this by "feel." If you pry too far from the fasteners, you will leverage the attachment point and bend the molding. Since I was replacing the molding, I didn't care if I trashed the old ones. If any old, broken molding clips snap off in the plastic channel "molding fastener," you can snake them out with a thin edge by sliding the broken pieces to the bottom of the molding fastener. New clips come already attached to the new molding.

When I removed the passenger side molding, the plastic molding fastener also pulled loose from the car, so that had to be repaired as well.

The service manual listed using a heat gun and double sided tape to replace and repair it. Instead, I bought a two-part epoxy and glued the fastener back in place, solid as a rock. The next photo shows the molding fastener glued and held into place with cardboard wedged between it and the windshield. Do not glue it to the windshield, glue it to the car body.

The temperature was very cold in the garage, so I let it sit for over 24 hours. The molding fastener pulling out would seem like a fairly common occurrence to me, so be prepared to fix it.

I should mention that I started this project in the winter, in a garage that was below freezing. After going through what I did, I learned why pros don't do this kind of work in the cold. I waited until the summer to finish the job. If you try and do it in a cold environs, the plastic and rubber is too stiff and brittle. Wait until it's nice and warm outside, or at least until you have a heated garage, lol at myself.

Once the old molding is out it's simply a matter of positioning the new molding and pressing it down into the plastic channel groove. Each clip should give a distinct, satisfying snap once it is seated in place. I ran a trickle of silicone spray into the groove of the molding fastener because the garage was so cold. The molding also snapped into place over the top-most, white, rectangular clip that was still mounted to the body.

There is somewhat of a "spongy" feel to the molding after it is installed when you press down on it, because of the soft weather stripping on the side of the molding that was in contact with the glass. This is normal, as I have compared it to many other OEM molding pieces that have never been changed out.

If you're taking off your windshield moldings to paint them, and not replace them, then you have to be sure to not damage them. If you're nervous or hesitant about this, then stop by any windshield repair shop. They are experts at removing windshield molding and can have yours off in a flash, for probably just a few bucks, if you have your girlfriend sweet-talk them just right ;c)

ROOF MOLDING (short pieces)

I thought the windshield molding would be harder than the roof pieces, but I spent much more time on the short little roof pieces. Remove the T-tops and open your rear hatch for access. Two white clips hold each piece onto the roof, and each clip slides and locks over a metal nipple that is part of the body of the car.

You should have ordered at least four of these white clips. I ordered one or two extras since I did not want to get into the middle of a job and then be held up because I broke a one-dollar clip. Study the clips closely on and off the car so you understand how they work. Once you see how they attach, you should be able to slide and lift off your old moldings. Mine slid toward the rear of the car to come off. Just tap lightly and see which direction they want to go. I wasn't worried about preserving any old parts since I had all new replacements, so I could afford to hack a bit. After you remove your old molding, your roof should look like the photo below before the new moldings are installed.

The clips have a right and left side, a front and a back. You will also notice that they have a ratchet, sliding mechanism to them for lateral adjustment. Start with them "centered," more or less. If one ratchets too far, just push it all the way through until the clip comes apart into two pieces and then reassemble it. Weird.

Press the clips into the molding pieces first as shown in the photo above. I tried every which way to mount these roof moldings, and this was the only way I could get it to work. Eyeball the position of the clips in the molding by holding them up to the little metal studs on the car body. The clips should be oriented so that once you slide and lock the molding pieces onto the car, the molding is positioned nicely. There really isn't a lot of room for error since the clips take up most of the available space on the underside of the molding.

Make sure you have the clips oriented so they both need to slide in the same direction to lock once mounted, otherwise, DOH! I installed mine such that the molding piece slid forward to lock. Installing the first one took me an hour of trial and error, and five minutes to do the second one. I tried putting the clips onto the car first, but then I could not get the molding to snap into place, no matter how hard I pressed down. This was kinda strange because I was able to snap the windshield molding into place over the same type of white clip. Go figure.

DOOR MOLDING

Next (as in six months later, lol at myself) I did the door moldings. I waited until I had my interior door panels off for a stereo install, and for warm weather. Here are a couple of links that contain good write-ups on door panel removal:

door panel removal as part of a stereo install

door panel removal translated from Japanese

Thanks Bernie, for those.

Removing and replacing the door panels is what takes the most time when replacing the door moldings. The molding pieces themselves basically just pry off and wedge back on. The reason the interior door panels need to come off is so that the molding edge can be pried from the inside without doing damage to any visible parts of your car body. There is one plastic nipple at the outside base of the door pillar toward the back of the door, that is attached to the molding piece. Pop the molding off of this nipple before you starting prying the whole piece off the door.

Then pry the molding loose from the inside of the door. Don't pry on the glass edge or you can break it.

When installing the new piece, first slide the front edge of the molding under the stanchion that holds the side mirrors in place.

Check the length at the other end, then just press straight down on the molding piece, and inch toward the back of the door. The photo shows me pressing down with the inside door panel already back on. My new tweeter is visible between my arm and mirror, which is why I had my door panels off :c) Since you will need to press down pretty hard, I recommend the door be closed so the hinges don’t get stressed. I did not worry about reattaching the plastic nipple piece at the base of the pillar as my molding pieces were plenty tight without it.

T-TOP MOLDING

Tools needed: Phillips screwdriver, flat screw driver or some other gentle prying tool, 10 mm socket, and some black RTV silicone. I did the whole job without replacing any weather stripping but I re-glued the old stuff back in place.

Basically there are three, large, main, structural pieces to the T-top - the glass, the inside plastic bracket, and the metal exterior body panel to which the molding piece is attached by five screws. Take your T-tops indoors to work on them.

You should disassemble the entire T-top, except for the locking mechanism, to get at the screws that are holding the molding in place. There was a recent, very helpful write-up by “PLEAZURE in CA” that got FAQ'd on how to get to these screws by drilling holes in the plastic bracket. That is an alternative method. I preferred not to drill holes since it is not that much harder to simply take the T-top apart. This also allowed me to refresh and repair the weather stripping that was deeper inside the T-tops with some silicone, which made my T-tops water tight, once again. Plus, I don't like drilling holes in my Z :c)

1) Remove inside shade cover from T-top if you have one, and use the cover as a tray for the screws you remove :c)

2) Pry off "open < > locked" button. Open handle, remove trim screw. Pry off and remove trim piece around handle. Leave handle open.

3) Remove one screw on each end of garnish cover and pry off garnish cover.

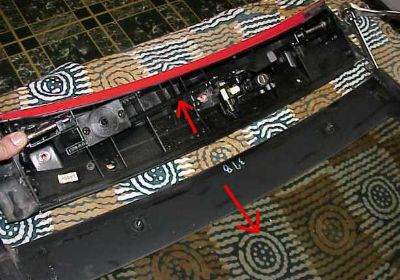

4) Remove five, 10mm nuts/screws holding plastic bracket. Two are flange nuts going through the glass of the T-top, the remaining three are Phillips screw nuts. Their locations are marked on the photo with red dots. Do not undo the screws to the locking mechanism.

5) Remove the two screws attached to the metal end brackets on both ends of the plastic bracket, through which the T-top locking rod extends.

6) Peel back the thick, large black rubber weather stripping, still leaving it attached to its aluminum bracket at the ends. You will see two middle screws, as shown in the photo below.

Remove these two screws. There are also two end screws that pass through the rubber that you access through holes in the rubber. Loosen the two end screws but keep the rubber attached to the aluminum bracket at the ends.

The end screws will sit nicely inside the rubber trim after they are unscrewed from the aluminum bracket. Remove the aluminum bracket from the rest of the T-top. There is a little silicone holding these pieces together, but they should peel apart easily once the four screws holding the aluminum bracket onto the metal exterior piece are removed.

7) Remove one small end screw on each the underside of the T-top. There is some silicone on these screw heads used as a sealer that you should replace when you put everything back together. These screws help connect the glass panel to the T-top bracket AND are the two end screws holding the molding piece to be replaced.

8) Separate the glass from the rest of the T-top by sliding it loose. There is a little bit of glue holding some rubber to the glass at the ends of the plastic bracket, but this is easily pulled loose. Do not lose the T-top bolts that go through the glass as they can fall out since the nuts are already removed.

9) Separate the plastic bracket from the metal exterior body piece by gently prying one of the metal brackets on one end free. Once you free one end of the plastic from this metal bracket, you can lift the entire plastic piece away. There is some adhesive weather stripping holding the plastic and metal pieces together. I reused all mine with a little help from some black RTV silicone.

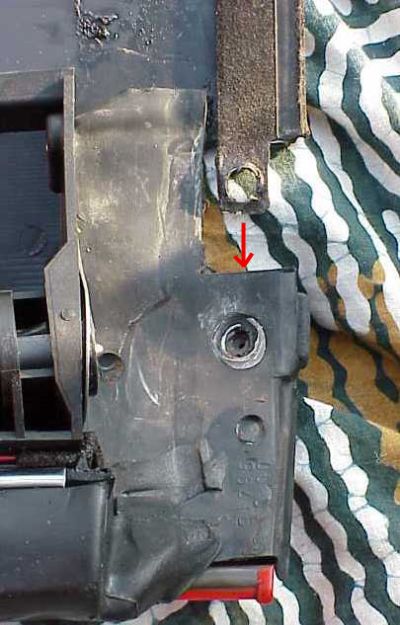

10) You should now have the metal exterior body piece that holds the molding completely free. On the underside of the metal exterior piece, there are three screws left holding the molding in place, shown marked with red dots in the photo. Remove the three remaining screws and the old molding falls off. The channel on the metal exterior holding my molding was pretty grimy so I cleaned it with Simple Green. I also put fresh silicone on the weather stripping seen just above the screws.

11) Install new molding with the three center screws. The end screws don't go in yet.

12) Reverse the above steps and put the whole T-top back together. Slide the plastic bracket back into metal exterior piece that holds the new molding. Replace the four screws in the metal end brackets that secure the ends of the plastic bracket. Slide glass back into metal / plastic piece. Note how the end metal screw holes on the glass piece insert in BETWEEN and underneath the rubber ends of the plastic bracket in the next two photos.

One important step to check at this point is to make sure the glass edge of the T-top is UNDER the molding on the outside. The edge of the molding on the glass side is soft rubber, and it can get turned under and folded back on itself. I used a thin edge to help settle the molding over the glass. Install the two T-top nuts and bolts that go through the glass. Do not over tighten these or you could break the glass :c(

Install the two small end screws that finish attaching the molding. Also, remember that these small screw heads take silicone sealant. Replace the large rubber weather stripping bracket with the four screws. Push the thick, rubber trim back into the groove on its bracket. Replace the three remaining main nuts in the plastic bracket. Replace garnish, its two end screws and trim piece over handle. Pop button back onto sliding lock. I did a final little detail on the soft edge of the molding with one of my favorite precision tools, so that it lay straight and smooth against the glass.

You are done :c)

As an added bonus, after I installed my T-top moldings, my slow, door leak drips went away. My leaks were at the front, top corner of the side window glass. I believe the leaks stopped as a result of mainly tightening all the screws, and refreshing the weather stripping with some silicone, and not because of the new molding itself.

| |